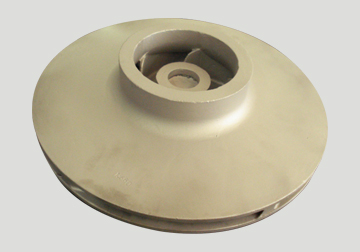

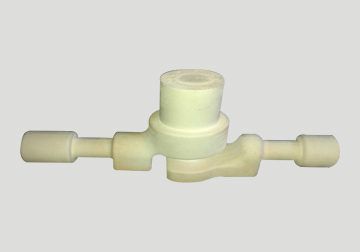

Various material specification being manufactured

The company manufactures all types of ferrous based castings conforming to various Indian as well as international standards. The most common are:

1. Stainless Steels & Corrosion Resistance Steels

Stainless Steel casting confirming to various standards like ASTM, IS, DIN, JIS e.g. CF8, CF3, CF8M, CF3M, CD4MCU, 17.4PH, CA6NM, CA 15, CA 40 etc.

2. Heat Resistance Steels

Heat Resistance Steel casting confirming to various standards like ASTM, IS, DIN, JIS e.g. grades HA, HH, HK, HT, etc.

3. Special & High Alloy Steels

Special Alloy casting confirming to various standards like ASTM, IS, DIN, JIS e.g. Alloy-20, Haste Alloy - A, Haste Alloy-B, Haste Alloy-C etc.

4. Plain & Low Alloy Steels

Plain & Low Alloy Steel casting confirming to various standards like ASTM, IS, DIN, JIS e.g. WCB, WCA, WCC, EN-8, EN-9, EN-19, EN-24, EN-55, etc.

5. low-temperature alloy steels

Alloy Steel casting confirming to various standards like ASTM, IS, DIN, JIS e.g. LCB, LCC, LC-6, CA 15, CA6NM, etc.

Dimension Tolerances:

Investment castings can be produced with a very close control dimension eliminating machining in some of the products. It’s to the buyer’s interest to develop the product with minimum machining allowance to enable him to take advantage of the process. General tolerances which can be achieved by this process are mentioned below. However if required still further tight tolerance, the same can be discussed with the manufacturer and then design the product accordingly.

Dimensions

The dimensions tolerances mentioned are as per Indian Standards 11166 Class II. All tolerances are in +/- tolerances.